DB7

Autocar

March 3rd 1993

Giles Chapman

courtesy and copyright of Autocar

www.autocar.co.uk

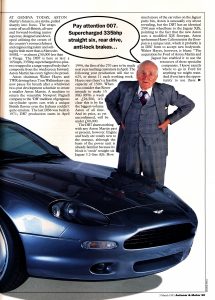

At Geneva today, Aston Martin’s future is, at a stroke, pulled sharply into focus. The wraps come off an all-British, all-new and forward-looking junior supercar, designed and developed utilising the cream of the country’s resourcefulness and engineering talent and selling for little more than a Mercedes 500SL – or almost £50,000 less than a Virage. The DB7 is here at last: a 165mph, 335bhp supercharged two-plus-two wrapped in a targa-topped body that’s composite from the windscreen forward. Aston Martin has every right to be proud.

Aston chairman Walter Hayes and TWR driving force Tom Walkinshaw can now pause for breath after a whirlwind two-year development schedule to create a smaller Aston Martin. A machine to return the venerable Newport Pagnell company to the ‘DB’ tradition of gorgeous six-cylinder sports cars with a unique British flavour even the Italians couldn’t quite emulate. The last DB6 was built in 1971; DB7 production starts in April 1994, the first of the 270 cars to be made next year reaching customers in April. The following year production will rise to 625, or about 11 each working week. Hayes says there’s a feasible capacity of 1500. When you consider that Rover intends to make 15 MG RV8s a week at £26,500, it’s clear this is by far the biggest-volume Aston of all time. And its price, as yet unconfirmed, will be under £80,000.

The DB7 shares nothing with any Aston Martin past or present, however. Engine and body are totally new to the marque, although the basis of the power unit is already familiar because its block is ‘stock’ straight six Jaguar 3.2-litre AJ6. How much more of the car relies on the Jaguar parts bin, Aston is unusually coy about revealing, but the DB7 has an identical 2591mm wheelbase to the Jaguar XJS, pointing to the fact that the new Aston uses a modified XJS floorpan. Aston spokesman Harry Calton insists the floorpan is a unique unit, which it probably is in DB7 form to accept new bodywork. Walter Hayes, however, is blunt: “The acquisition by Ford of Aston Martin and Jaguar has enabled it to use the resources of these specialist companies. I know exactly where to go in Ford for anything we might want. And if you have the opportunity to use these facilities you’d be damn silly not to.”

Without taking a DB7 apart, we can’t know how much of the car was conceived at Browns Lane. We do know, however, that shortly after Ford’s takeover of Jaguar and the subsequent abandonment of the XJ41 ‘F-type’, Walkinshaw – Ford’s favourite man in a crisis – was commissioned to build a quickie F-type image car, Project XX, probably using the twin-turbo six-cylinder engine designed for XJ41. It definitely used XJS internal pressings and was wrapped in an F-type lookalike body by TWR’s Ian Callum, designer of the DB7 you see here.

When Ford realised Jaguar’s problems needed more than just an image boost, XX was shelved. But Hayes, to his eternal credit, realised XX contained the guts of the cheap car Aston was dying for. Prototypes were already running when NPX (Newport Pagnell Experimental) ‘went public’ in June last year.

He recognised early on in the car’s development programme that sticking to targets was vital. “It’s difficult to cost-control an £80,000 car, even if it doesn’t sound it, but we had to set precise volumes, objectives and price,” he says. “We couldn’t have an engine that cost £21,500 and 56 hours to hand-build, and Newport Pagnell is too restricted to make a volume car- there’s no room there. So we had a manufacturing challenge rather than a design one; I didn’t start where the mechanicals were concerned.”

As a result, Hayes formed Aston Martin Oxford with Walkinshaw’s TWR Group, and the DB7 was engineered by Jaguar-Sport, beginning in early 1990, at AMO’s Kidlington base. It will be built at TWR’s Bloxham factory, which will be enlarged to cope after the final XJ220 is finished.

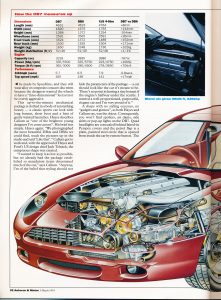

The engine, the heart of the DB7, has its own all-alloy head, with four valves per cylinder and twin chain-driven overhead camshafts. Electronic sequential injection provided the fuel feed and a three-way catalytic converter cleanses the exhaust. An integral part of the mechanical package is the single Eaton supercharger, water-intercooled and fitted with a bypass valve. Aston uses two of these American units on its Vantage. Maximum boost pressure is a hefty 14psi.

The philosophy behind specifying this performance booster is to give lots of extra and usable torque from a high-revving, short-stroke engine without the lag associated with turbocharging. Also, according to Walkinshaw, it should satisfy markets like the US, where there’s a strong emphasis on ‘step-down’ performance. “In the US, where there’s a strong emphasis on ‘step-down’ performance. “In the US, the 0-30mph speed is of primary importance,” he says. The computer-controlled Zytec engine management system features a single-speed density flow meter. On-board diagnostics self-check all engine functions, and fuel is fed through two independently controlled pumps. Aston’s figures state that maximum power is 335bhp at 5600rpm. Peak torque is said to be 368lb ft at 3000rpm, with 90 per cent of peak torque coming in the 2200-5500 rpm range. In comparison, JaguarSport’s normally aspirated XJR-S manages 333bhp at 5250 and maximum torque at 365lb ft at 3650rpm – from six litres and 12 cylinders.

The DB7 puts its power down through the rear wheels via a five-speed Getrag manual gearbox or an automatic. Which type was not confirmed as we went to press, but prototypes have used the electronic GM four-speed unit fitted to V12 Jaguar XJSs. The final drive is 3.54:1, with a limited slip differential as standard.

Aston’s performance figures for the car, which weighs 1650kg, quote an impressive 0-60mph time of 5.5secs, with 100mph attainable in just 13 secs – testament to the tremendous spread of torque. Top speed is a claimed 165mph. Average fuel consumption is about 25mpg, but Aston claims a remarkable 37.2mpg at 56mph.

Suspension is independent all round, with double wishbones, coil springs and gas-filled telescopic dampers. At the front is an anti-roll bar, while the rear double-wishbone set-up incorporates longitudinal control arms.

Teves anti-lock brakes are standard, with 285mm ventilated discs at front and 295mm solid outboard discs at rear. Steering is power-assisted rack and pinion, with a nimble 2.54 turns lock to lock; the steering column is tilt-adjustable.

Eighteen-inch allow wheels are shod with Bridgestone 245/40 ZR18 tyres. The final design of wheel- TWR’s own- has still to be decided, although they’ll be made by Speedline, and they will wear alloy or composite concave disc trims because the designers wanted the wheels to have a “three-dimensional” feel yet not be overtly aggressive.

This up-to-minute mechanical package is clothed in a body of astonishing beauty – a classic sports car look with long bonnet, short boot and a hint of gently waisted haunches. Hayes describes Callum as “one of the brightest young designers I’ve ever come across”. His brief was simple. Hayes again: “We photographed the most beautiful DB4s and DB6s we could find, suck pictures up in the studio and said ‘Like that’.” Callum got to work and, with approval of Hayes and Ford’s US design chief Jack Telnack, the sumptuous shape was created.

“I wanted to keep it as low as possible, but we already had the package established so mandatory items determined much of the car,” says Callum. “Anyway, I’m of the belief that styling should not hide the parameters of the package – a car should look like the car it’s meant to be. There’s no point in having a tiny bonnet if the engine’s halfway under the scuttle. I wanted a well proportioned, purposeful, elegant car and I’m very proud of it.”

A shape with no styling excesses, no “gadgets and gizmos”, as both Hayes and Callum say, was the object. Consequently, you won’t find spoilers, air dams, side skirts or pop-up lights on the DB7. Quad headlights are concealed behind faired-in Perspex covers and the petrol flap is a plain, painted steel circle that is opened from inside the car by remote button. The traditional Aston grille shape, with ‘chipped-off’ corners, is incorporated, encasing a bold eggcrate-pattern grille. Beneath that is a mesh-covered additional air intake, flanked by high-intensity driving lights in their own recesses. At the rear the wing line tapers to a softly squared-off tail, with a simple, partially recessed rectangular rear window. The aerodynamics are good: a 0.31 Cd and a coefficient of lift of 0.25.

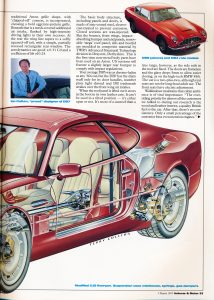

The basic body structure, including panels and doors, is made of zinc-coated steel, electrocast-treated to prevent corrosion. Closed sections are wax-injected. But the bonnet, front wings, impact-absorbing bumper and end panels, removable ‘targa’ roof panel, sills and bootlid are moulded in composite material by TWR’s Advanced Structural Technology division in Draycott, Derbyshire. This is the first time non-metal body parts have been used on an Aston. US versions will feature a slightly larger rear bumper to comply with impact regulations.

Your average DB5 was as chrome-laden as any ‘60s car, but the DB7 has the shiny stuff only for its door handles, number plate light shroud and DB trademark strakes over the front wing air intakes.

When the roof panel is lifted out it stows in the boot in its own leather case. It can’t be used in a tilted position – it’s either open or not. It’s more of a sunroof than a true targa, however, as the side rails in the roof are fixed. The doors are frameless and the glass drops 5mm to allow easier closing, as on the high-tech BMW 850i. The car is a two-plus-two, although rear seats are not for long-haul adult use. The front seats have electric adjustment.

Walkinshaw maintains that cabin ambiance is of vital importance: “The overriding priority for almost all the customers we talked to during our research is the wood and leather interior, a quality British feel to the car. After that, there’s no consistency. Only a small percentage of the customer base even mentions engines.”

The interior is mainly the work of 29-year-old designer Neil Simpson. He and Callum worked together at Ford on the design of the Escort Cosworth and are both ex-Royal College of Art students. Under Callum’s direction, Simpson’s design is a sculptured shrine to hand-crafted Connolly ‘natural look’ leather and Wilton carpet. Burr walnut, however, is kept to a tasteful minimum, applied to doors and centre console, with a thin strip on the dash. Echoing the plain and functional interiors of the ‘60s DB Astons, Simpson says: “We didn’t see why the interior had to be olde worlde.”

Much as Aston insists superfluous electric toys have been left out, the interior is fully equipped with air conditioning, heated front and rear screens and mirrors, interior lights and cruise control, all co-ordinated from the centre console. Their controls have Aston buttons fronting Ford and Jaguar parts bin ‘plumbing’, useful cost-saving no owner is likely to object to. Fresh air vents and other small items of switchgear are similarly proprietary yet carefully integrated into Simpson’s organic and enveloping interior. You might also notice the high transmission tunnel and the handbrake situated beside the driver’s seat on the right- pointers to XJ-S-related structure below.

A four-speaker Sony music system is standard, with CD player optional, and the central locking incorporates an alarm/immobiliser. The carpeted boot has spare wheel, battery and tool kit underneath it, and a low sill. Luggage capacity is 0.17 cubic meters.

The DB7 has been fully engineered with Ford’s help to take airbags for driver and passenger. It’s uncertain whether they’ll be standard in all markets, although Aston insiders think this is probable.

There’s just one version of the DB7, options limited to choice of transmission and in-car entertainment only. This is a deliberate policy. “It’s a fully specified car with no options,” says Hayes. “That’s part of the secret of doing it for £80,000.” As part of that consolidation, there will be a choice of just six colours, mostly metallics and including, of course, a green. The car being revealed at Geneva today is finished in metallic graphite silver-grey.

There is, however, more than a year to go before it goes on sale. If you turn up on the Aston Martin stand with your cheque book – and deposits are being welcomed – you may well have some input into the final colour and trim detail choice yourself and become part of Aston Martin’s most historic day since David Brown arrived in 1947. The chance to try the DB7 on the road will be one of our highlights of the coming 12 months.

How the DB7 will be built

Aston’s new supercar is the baby of a proud, 70-strong team at the JaguarSport engineering and styling centre at Kidlington, Oxford, and it will use the same assembly line at TWR’s Bloxham factory as the outgoing Jaguar XJ220.

Although the final who-does-what is still to be confirmed, Aston Martin has revealed that painted steel bodies will arrive from Motor Panels’ Coventry factory by road. Powerplants will be produced at an as-yet unnamed Jaguar facility – likely to be the Radford plant in Coventry, where other AJ6 engines are made – and then sent to Bloxham, where they will be mated to other brought-in ancillaries.

TWR’s Draycott plant will mould the composite body panels, while the leather-covered seats (the frames of which are off the shelf), other leather trim parts, hand-cut walnut and carpet for the interior will arrive in batches from Aston Martin’s Newport Pagnell factory on a daily shuttle truck.

Assembly of up to 625 cars a year will be overseen by former Ford man Mike Moreton, who is responsible for production of the Jaguar XJ220 and who also supervised the assembly of the 200 Ford RS200 Group B rally cars at Reliant.

What happens now?

The DB7 is destined for an on sale date of April 1994 at a price less than £80,000 and it’s shown for the first time at Geneva today. The shape of the car and its dimensions have been signed off but there may be detail changes to trim. Aston has still to decide which automatic transmission will be offered, which markets will receive airbags as standard, and what the final colour choice will be. Similarly, the exact choice of interior trim colour is not yet set in stone- the Geneva car features ‘oxblood and parchment’, a sort of crimson red and cream.

Deposits will be accepted from today for the car, to be sold in a single version through an expanded network of Aston dealers. Aston chairman Walter Hayes has instigated a geographical study of where this network is lacking. “For instance, we only have one dealer for the whole of France,” he says, claiming current dealers were “much, much more bullish about the enterprise than I would wish them to be.”

Service intervals will be every 6000 miles but Aston Martin says it will not be serviceable by Jaguar dealers. “Aston Martin is a completely separate franchise,” says TWR chief Tom Walkinshaw.

Initial production will be for the UK, Europe, the Middle and Far East, with left-hand drive production taking priority. The car revealed at Geneva today is a left-hooker.

Road testing of the DB7 has already taken place in the UK, Australia and Arizona. It’s also been tested at Ford’s Lommel test track in Belgium and at the Millbrook proving ground. Crash testing had already been done midway through 1992.

Walkinshaw has hinted that there’s the possibility of a traction control system being available at a later date, and Aston insiders talk of plans for a Volante convertible version in two or three years’ time.

No one within Aston Martin will reveal the size of investment Ford and TWR are making to get DB7 into production; Hayes states that he expects Aston Martin Lagonda, however, to be back in the black in 1993, after rationalisation of the Newport Pagnell factory. The ‘V Range’ (Virage, Volante and Vantage) is now group assembled, and Aston expects to make about 60 of these cars this year.